PORTABLE GOLD WASH PLANTS

Our gold mining equipment plant has a full power 4 point drive system (which eliminates the chain drive) is fully reversible, and has a full variable speed control. Our Gold Trommel has a extra heavy shell and is completely lined with abrasion resistant plate in all wear areas, Gold Trommels have additional reinforcement in drive locations, and incorporates oversized shafts and bearings. Testing showed that some of the biggest complaints with Trommels is screen blockage, so we have taken and installed full polyurethane Tapered Relief octagon screening media to help eliminate this issue, and expensive but needed adaptation. Another advantage with this screen media is it has 10 to 15 times of life of steel. Additionally, the screen media snaps into place which only take minutes instead of days or weeks as with some other systems.

With machine properly equipped and proper screen sizing and even fed material test plant was able to achieve up to 150 Tons Per Hour, ST rates this machine between 75 to 100 ton per hour with material as follows:

Results will vary depending screens, water and material conditions. Does not include generator or water pump.

Trommel design uses a 12 sided polygon,1150mm diameter drum,2700mm of pre-scrub area with reinforced drive rings for Trommel drives.

Trommel has replaceable wear plates in all wear areas including Flytes. Trommel uses Polyurethane screens with tapered relief holes which we recommend.

Internal spray tube with interchangeable brass spray nozzles for final rinsing action.

Star Trace offers turnkey solutions for gold trommal plants. We are one of the leading project suppliers for gold processing plants and we work closely with our customers to fulfill their specific needs for a customized packaged solution. Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of gold trommal plant & equipment.

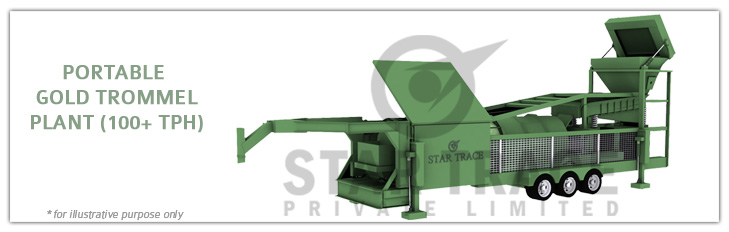

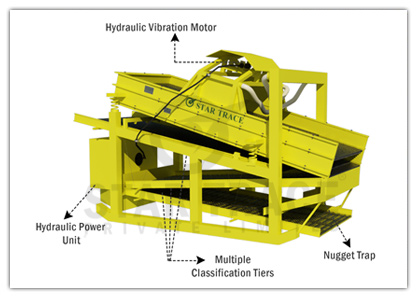

Star Trace offering the Gold Wash Plant in the remarkable qualities with latest technology. Star Trace manufacturing a several different types of gold wash plants from 50-500tons per hour. In all conditions each plant consists of proportionate sized of 3 sluice boxes and utilized 3 different types of riffle designs.Star Trace Gold wash plant is a complete portable plant, no need to setup additional sluice boxes or separators in the plant. In the top of the plant, grizzly bar section it will take up to 36 inch rocks. The classification begins when the material is placed on the grizzly bar and the high pressure of water should separate the smaller material from the larger rocks. Then the separated material is dropped below to enter into the sluice boxes and the large rocks are disposed. It consists of 3 independent adjusting sluice boxes. To collect the nuggests, most of the materials continues through the smaller area while at the nugget trap allows larger materials to bypass the system to rejoin at the final stage for sluicing.

The cleaning out of the machine is very easy, efficient and quick. By using the spin clamps that release the trays to reveal the miners moss below

Star Trace Gold wash plant is fully hydraulic with no needed of electricity. Our device are driven directly by the hydraulic motor with no chain or belt drives for the shaker weight, which some mechanical parts need to be break down.

Star Trace hydraulic system is lower fuel consumption with less mechanical breaking points. Our machines are used in the shaker system that come with fully equipped grease points which leads to use for many years. For more portability, the machines are highly portable and can be mounted on trailers.